Contact Us

If you have any questions,please contact us,we will get back to you as soon as possible.

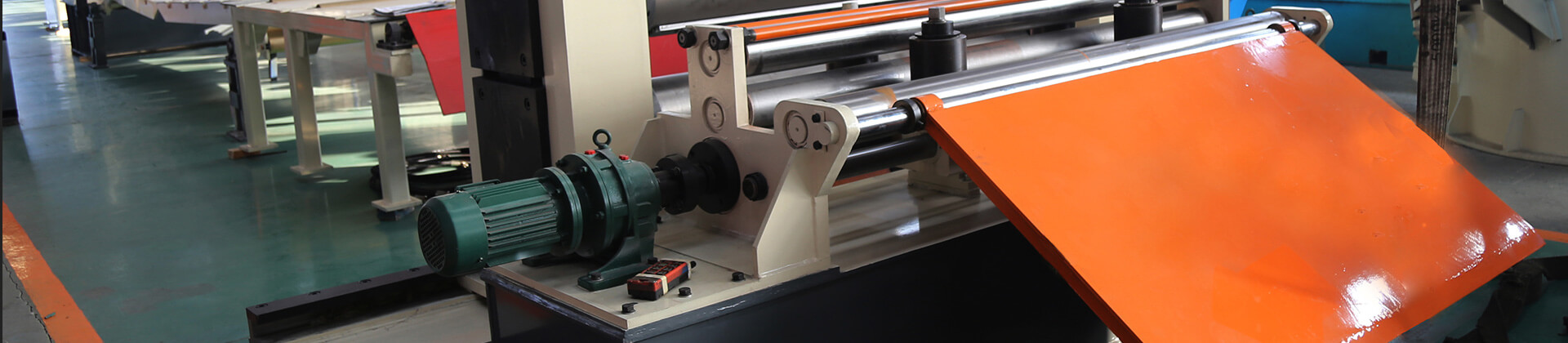

ERW50 welded tube production line, first in the preparation period of steel coil will take strip coil to uncoiler and the head and tail of strip coil butt welding. And then deliver it into accumulator, steel strip is pulled out from the accumulator with a constant speed through the unit. The steel strip is formed into open tube in the forming unit. Then weld it into straight welded pipe with solid state high frequency, and water cooling after elimination of external burr. Round tube and square rectangular tube size in the sizing machine. After sizing the pipe is straightened in Turkey head and then cut into the required length of flying saw. After steel pipe cut to sizing length, through output roller track push it from flying saw into table stand to test.

This production line can meet the process requirements of square tube, rectangular tube, round tube. ERW50 mill is a special equipment producing straight welded pipe for metallurgy, construction, transportation, machinery, vehicles and other industries. Producing round tube and square rectangular tube with the requirements of cold roll forming and high frequency welding and using cold rolling and hot rolling strip as raw material. In the process of forming adopts "W" forming technology. The deformation process of the forming mode makes the stress more reasonable, and the material deformation of the machine frame is more perfect.

Notable characteristics of the whole set unit: high speed, high efficiency, time saving and labor saving.

Unit features: high strength, strong rigidity.

|

|

|

By continuing to use the site you agree to our privacy policy Terms and Conditions.