Contact Us

If you have any questions,please contact us,we will get back to you as soon as possible.

The GI (galvanized iron) pipe production line is able to produce galvanized iron pipes of round pipes 1/2’’—6’’

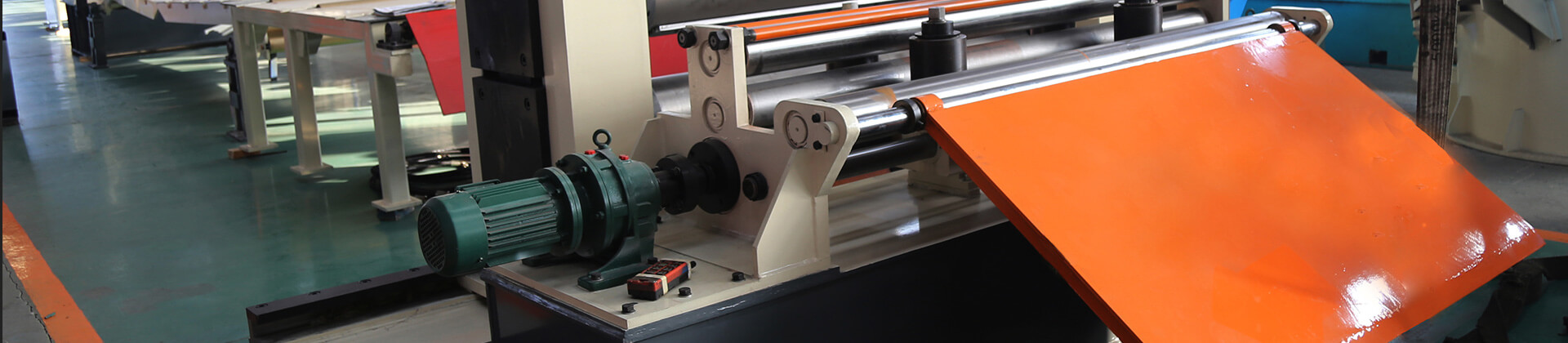

Steel pipe hot-dipped galvanized is a technology that dipping steel tubes into the liquid zinc and make the steel tubes surface to be coated with zinc layer. This process can be divided into four steps:

1): the steel pipe surface pre-treating, that is cleaning, degreasing, pickling, water cleaning, solvent processing and drying, this step could ensure the next step galvanized layer own good adhesion with the steel pipe surface.

2): Steel tube hot dip galvanized, after pre-process, dip surface clean steel tubes in zinc liquid, for hot dip galvanized processing.

3): Galvanized layer processing, injection treatment on the surface of the zinc coating, galvanized steel pipe cooling, and passivation in order to protect the galvanized layer.

4):Hot dip galvanized tube marking, inspection and packing.

This process ensures the uniformity of steel tube galvanized layer, and has good corrosion resistance and adhesion strength, the mature technology is approved and favorable by current galvanizing industry.

|  |  |

By continuing to use the site you agree to our privacy policy Terms and Conditions.